- WOODPECKER 3.2 GRBL BOARD MIN Z SWITCH HOW TO

- WOODPECKER 3.2 GRBL BOARD MIN Z SWITCH DRIVERS

- WOODPECKER 3.2 GRBL BOARD MIN Z SWITCH CODE

There are many recommendations about adding resistors and shielding cables and re running limit switch wires away from power wires etc but I feel its all quite unnecessary.

This problem seems to plague everyone who tries to put limit switches on. but its all difficult, sometimes expensive and unsightly and usually not a perfect solution. Much discussion, on the Shapeoko & Shapeoko2 side, falls around using low value pull up resistors or special shielded cables and cable routing paths. You need 100% accurate limit sensing, 1 false limit trigger can ruin your whole print or CNC job.

WOODPECKER 3.2 GRBL BOARD MIN Z SWITCH HOW TO

Many forums have discussion on how to stop the false triggers and most of it doesn't seem to work 100%. Limits switches or 'end stops' as they are known to the 3D printing community can be troublesome for Hobby CNC and 3D print setups.

WOODPECKER 3.2 GRBL BOARD MIN Z SWITCH DRIVERS

Also if you do not directly look into the beam :-) It is important to wear safety goggles.The laser does never ran run out of instructions (in contrast to Laserweb where this sometime happens). Universal G-Code Sender works also very well for sending the generated gcode.Meanwhile the laser would produce a hole.

WOODPECKER 3.2 GRBL BOARD MIN Z SWITCH CODE

This is because LaserWeb sometimes takes its time till the next G Code is sent.

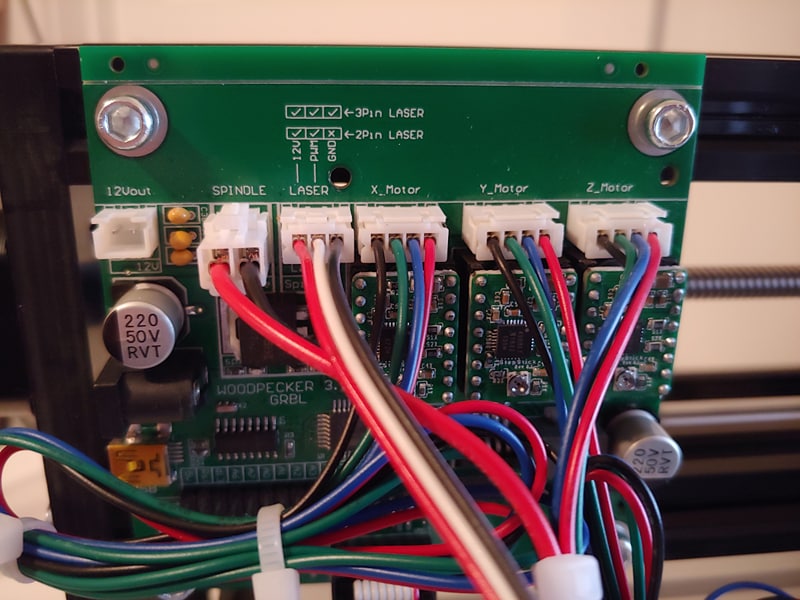

The results are (if you have figured out the parameters) quiet OK.The quality of the Eleksmaker Frame and controller is good.I created a new profile (EleksMaker_A3) which can be imported into Laserweb with Settings -> Tools -> LoadĪfter working for a few hours with the setup I can say that i does what it is supposed to do. S1 - S255 sets the power of the laser (0 - 100%).M4 turns the laser on with adaptive power,.M3 turns the laser on (with constant power),.The usage of the laser within g-code is simple: The power setting for the laser comes in form of a TTL compatible PWM signal directly from the Pin 11 of the controller-board: Therefore I purchased an Y-Adapter that splits the power from the supply towards the controller board and (unswitched) to the white connector of the laser-controller. This has the advantage that the laser is being cooled if the board is turned of. I decided to power my laser-board independent from the controller-board. Every other 2.54 mm (=100mil) connection jack should do as well. The plugs that i have used I snapped of from the HDD Led and Reset Button from an old computer.

It turned out that it was not that hard: One of the connectors of my laser board was straight forward: +12V | GND. The next issue was, that the controller board has a 3-pin connector (the second from top left), but my laser has two 2-pin connectors. So i decided to get a new one with 72W power (12V, 6A). The first issue was that the ManaSE controller-board came with a power supply which could not be used in Austria. All holes and threads were already there. The advantage of this approach is, that there was no need to modify the laser or the acrylic part of the frame.

0 kommentar(er)

0 kommentar(er)